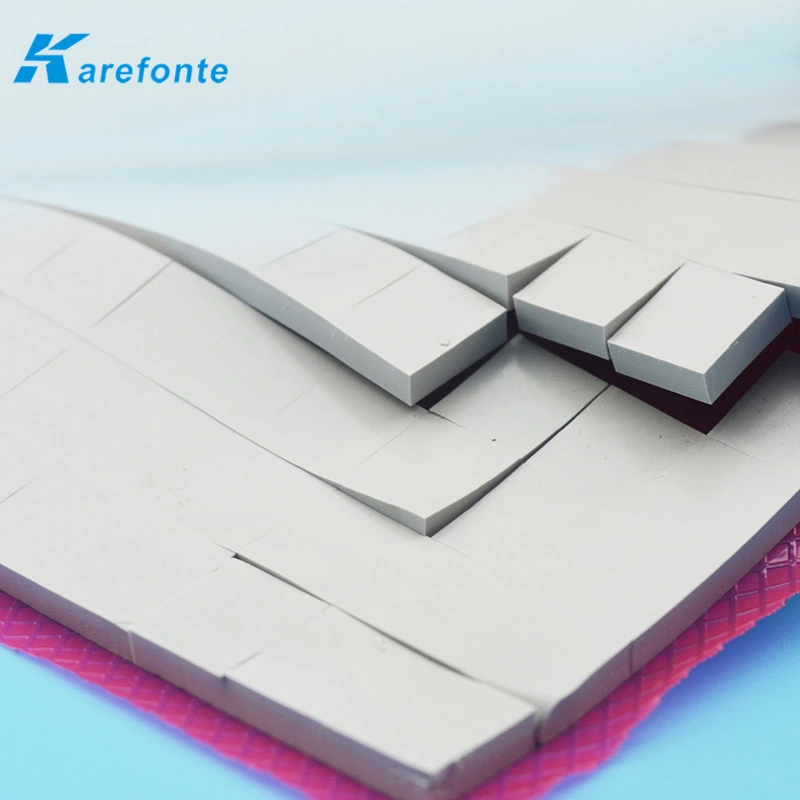

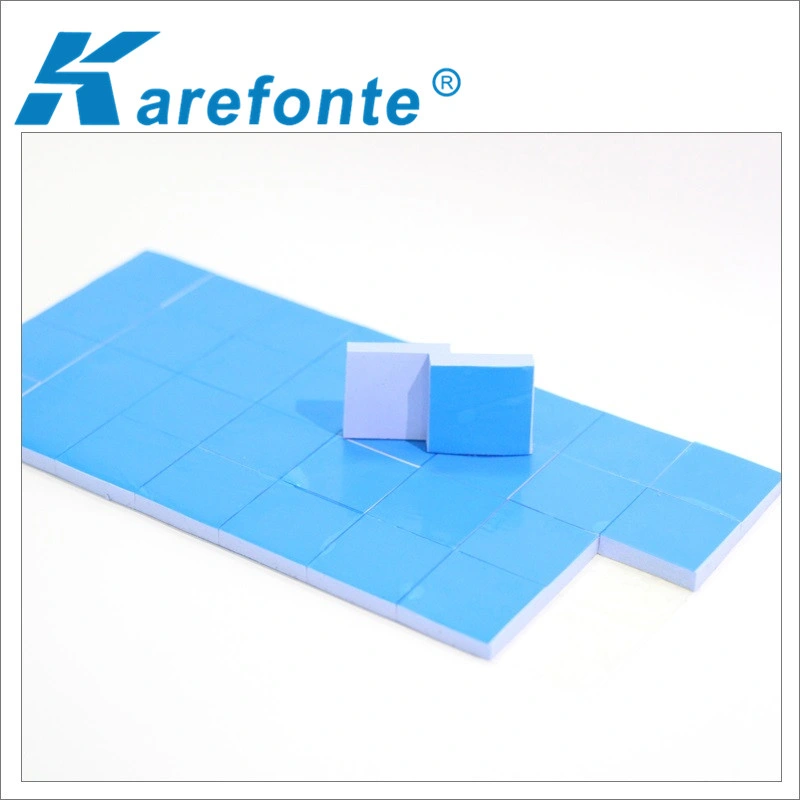

Thermal Conductive Compound Pad For Heatsink CPU VGA Chip Good Quality

Thermal pad has excellent thermal conductivity and electrical

insulation performance. Not only satisfy for majority electronic

products thermal insulation requirements, but also widely

used in the thermal requirements that are not too high in

electronic products. With the stable heat conduction

performance, and the product also has the viscosity, easy to

use.

Thermal pad is using soft silicone material heat-conducting,

stable insulation performance, use in transmission interface

between the electronic equipment and heat sink, which

achieve heat transfer and insulation effect.

insulation performance. Not only satisfy for majority electronic

products thermal insulation requirements, but also widely

used in the thermal requirements that are not too high in

electronic products. With the stable heat conduction

performance, and the product also has the viscosity, easy to

use.

Thermal pad is using soft silicone material heat-conducting,

stable insulation performance, use in transmission interface

between the electronic equipment and heat sink, which

achieve heat transfer and insulation effect.

Applications:

1.LED lighting, lighting equipment

2.Household appliances LCD display

3.Between semiconductor and heat sink

4.Communication product, smart phone, tablet .

5.Desktop, notebook and other portable computer

6.Large power supply etc.

Performance and characteristics:

1.High thermal conductivity, heat transfer coefficient1,1.5,2.5,3.6,4.6,5.2, 7,8,10,11,13,15W/m-k

2.Stable performance, low thermal resistance, effectively improve the heat transfer speed

3.Low hardness, its viscosity high, easy to use

4.V-O certification standards

1.LED lighting, lighting equipment

2.Household appliances LCD display

3.Between semiconductor and heat sink

4.Communication product, smart phone, tablet .

5.Desktop, notebook and other portable computer

6.Large power supply etc.

Performance and characteristics:

1.High thermal conductivity, heat transfer coefficient1,1.5,2.5,3.6,4.6,5.2, 7,8,10,11,13,15W/m-k

2.Stable performance, low thermal resistance, effectively improve the heat transfer speed

3.Low hardness, its viscosity high, easy to use

4.V-O certification standards

Specification:

1.Standard size : 200mm*400mm, 300mm*400mm, according

to customer needs cutting type.

2.Basic thickness 0.3mm~15mm, special thickness size can be customized

3.Its slightly viscous, if need to strengthen the adhesive can be according to customer's requirement

4.Product color is mass production color, special color can be adjusted to actual situation .

5.thermal conductivity low than 9W,the thinnest thickness is 0.25mm

thermal conductivity high than 9W,the thinnest thickness is 1.0mm

1.Standard size : 200mm*400mm, 300mm*400mm, according

to customer needs cutting type.

2.Basic thickness 0.3mm~15mm, special thickness size can be customized

3.Its slightly viscous, if need to strengthen the adhesive can be according to customer's requirement

4.Product color is mass production color, special color can be adjusted to actual situation .

5.thermal conductivity low than 9W,the thinnest thickness is 0.25mm

thermal conductivity high than 9W,the thinnest thickness is 1.0mm

| Test Item (Unit) | Numerical Value | Testing Method | |||||||

| Model No. | PM150 | PM200 | PM200s | PM260 | PM300 | PM350 | PM460 | PM500 | |

| Thickness (mm) | 0.25-18 | ASTM D347 | |||||||

| Color | Grey/Blue | Black | Pink | Green | Yellow | Grey | Blue | Blue | Visual |

| Working Temp(ºC) | -50~200 | TGA+DMA | |||||||

| Thermal Conductivity (W/m-k) | 1.5 | 2.0 | 2.0 | 2.5 | 3.0 | 3.5 | 4.5 | 5.0 | ASTM D5470 |

| ThicknessTolerance (mm) | 0.16±0.01 | ASTM D347 | |||||||

| Volume Resistivity (Ω-cm) | 10^12 | 10^15 | 10^17 | 10^16 | 10^16 | 10^16 | 10^16 | 10^16 | ASTM D347 |

| Dielectric Strength (KV) | 4.5 | 4.5 | 6.0 | 5.0 | ASTM D149 | ||||

| Hardness (shore A) | 30±5 | 30±5 | 25±5 | 20±5 | 35±5 | 40±5 | 45±5 | 50±5 | ASTM D2240 |

| Specific Gravity | 2.05 | 2.6 | 2.8 | 3.0 | 3.15 | 3.2 | 3.5 | 3.5 | ASTM D792 |

| Tensile Strength (kg/cm^2) | 15 | 40 | 70 | 50 | 52 | 60 | 70 | 65 | ASTM D412 |

| Elongation (%) | 48 | 48 | 60 | 55 | 55 | 58 | 68 | 57 | ASTM D412 |

| EP(12) | Check out | IEC 62321 | |||||||

| Halogen(4) | Check out | EN 14582 | |||||||

| Flame Rating | 94V-0-1 | NO:E34163 | |||||||

FAQ

Q:Can we get the sample? If can , how to get it ?A:Yes , we can offer you the free sample if have in stock , but not include the shipping cost . Please feel free to contact to our sales if you need the sample.

Q:How can you guarantee the quality ?

A:With advanced professional machine and testing equipment,we ensure 100 % quality before shipment.

Q:Can we OEM or according to our requirement to cut the

size ?

A:We are a China Manufacture specialized in the thermal insulation materials, for example,Silicone Rubber pad,Thermal tape,Thermal Grease,Silicone Cloth with more than 11 years old.

Q:What payment term is available?

A:Bank transfer , Paypal ,Western Union , Master Card ,VIS.

Q:Can we get the sample? If can , how to get it ?A:Yes , we can offer you the free sample if have in stock , but not include the shipping cost . Please feel free to contact to our sales if you need the sample.

Q:How can you guarantee the quality ?

A:With advanced professional machine and testing equipment,we ensure 100 % quality before shipment.

Q:Can we OEM or according to our requirement to cut the

size ?

A:We are a China Manufacture specialized in the thermal insulation materials, for example,Silicone Rubber pad,Thermal tape,Thermal Grease,Silicone Cloth with more than 11 years old.

Q:What payment term is available?

A:Bank transfer , Paypal ,Western Union , Master Card ,VIS.